Date | 2024-09-03 17:44:17

In the intricate world of metalworking and manufacturing, the role of tooling cannot be overstated. Among the myriad of precision instruments, the blanking die stands as a testament to engineering ingenuity, revolutionizing the production of flat, accurately cut sheet metal parts. This article delves into the intricacies of blanking dies, exploring their fundamental principles, versatility, and the critical role they play in modern manufacturing processes.

The Essence of Blanking Dies

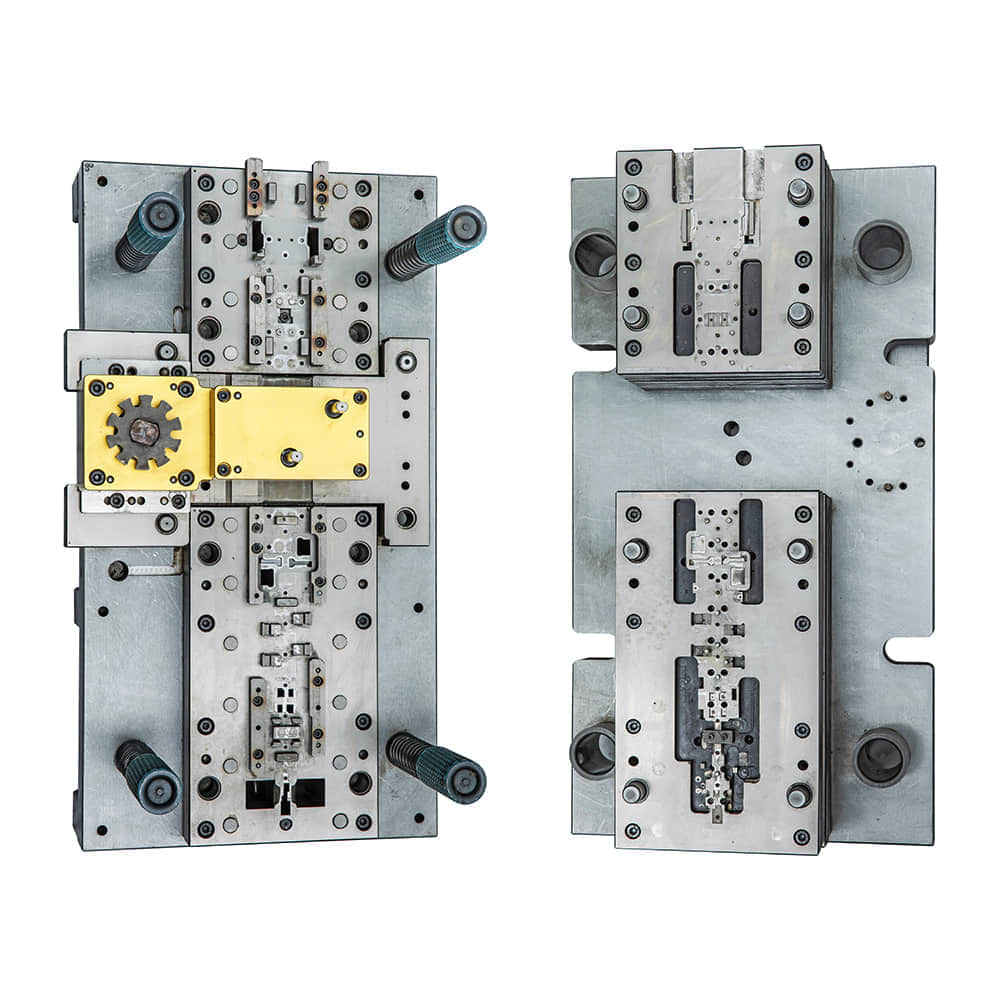

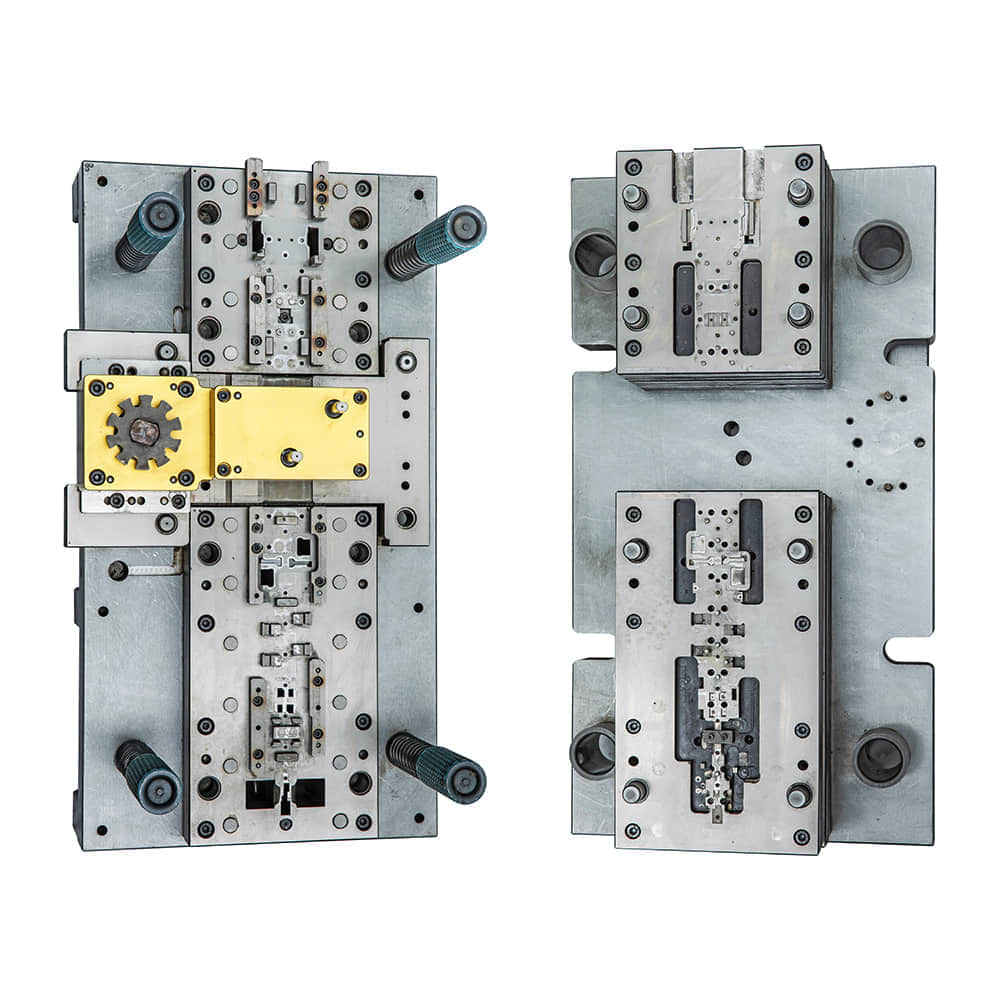

Blanking dies are specialized tools employed in punch presses or presses that utilize a combination of an upper punch and a lower die to separate a piece of sheet metal, known as a blank, from the surrounding material. This process, termed blanking, differs from punching primarily in that it involves completely severing the material along the entire perimeter of the desired shape, often leaving a smoother edge compared to punching, which creates a hole. The precision and accuracy of blanking dies are paramount, ensuring that the resulting blanks meet stringent dimensional and quality standards.